AUTOCARE: TRANSMISSION SYSTEM 2

Transmission system 2

In this session, we shall discuss the axle, which transmits power to the wheel. It plays a crucial role in the movement of a vehicle.

Propeller Shaft.

This is a shaft which transmits power from an engine to the wheels of a motor vehicle. It is a hollow tubular shaft and consists of mainly three parts

1. Shaft: It mainly bears torsional stress produced due to twisting. It is usually made of tubular cross section.

2. Universal joints: One or two universal joints are used, depending on the type of rear axle drive used. The universal joints help in the up and down movements of the rear axle when the vehicle is in running condition.

3. Slip joint: Depending on the type of drive, one slip joint may be there in the shaft. This serves to adjust the length of the propeller shaft when demanded

by the rear axle movements.

Front and Rear Axle

Front axle

Front axle carries the weight of the front portion of the automobile as well as facilitates steering and controls the rolling of wheels. It also absorbs road shocks arising due to road surface variations. In case of a commercial vehicle the front axles are generally dead axles. The front axle is designed to transmit the weight of the automobile from the springs to the front wheels, turning right or left as required. To prevent interference due to front engine location, and for providing greater stability and safety at high speeds by lowering the centre of gravity of the road vehicles, front axle includes the axle-beam, stub-axles with brake assemblies. The axle is made of I-section at centre and of circular or elliptical section in the ends since it has to bear the bending stress and torsional stress. In order to lower the chassis height a downward sweep is provided at the centre of the beam axle.

The main beam axle is connected to the stub axle with a king pin. The front road wheels are mounted on the stub axle. For smooth steering effects and maintaining proper control, the front axle of a car is supported with an independent suspension system.

The strut and coil spring allows the wheel to move up and down but does not allow to change the driving angle of axle shaft to transmit the drive smoothly. It also allows the wheel to rotate freely. This supports in steering the vehicle.

Rear Axle

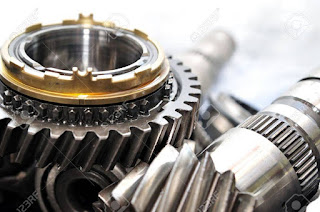

Like the front axle, the rear axle is also made of drop forged steel. The rear axle bears the weight of the vehicle body and load with springs. It enables to transmit the driving and breaking torque to the chassis frame and body of the vehicle. It also bears the side thrust or pull due to any side load on the wheel. It supports various parts like bevel pinion, bevel

gear, cage of sun gear and star pinions, axle shafts, and different support bearings.

It is important to note that rear road wheels are mounted on the axle shaft and the differential mechanism enables the outer wheel to move faster than the inner wheel while taking a turn

Join the Community

Instagram: https://instagram.com/thetellrhodescommunity

Facebook: The Tellrhodes Blog

WhatsApp: https://wa.me/2348071110893

Gmail: tellrhodes@gmail.com

Comments

Post a Comment